テクノロジー

Technology

- HOME

- ABOUT EXHAUST SYSTEM

- テクノロジー

FUJITSUBO Technology

- Japanese

- English

FUJITSUBOのスピリッツは常に「最高の製品を生み出すこと」。それは1931年創業以来、変わることはありません。「最高の製品」。それはマフラーやEXマニホールドなど、単にパーツとしての高性能、高品質だけに止まらず、人間の持つ感性を内包した製品のことであると考えます。人、クルマ、社会、環境など、すべてが一体となった研究、開発を行い、豊かな感性と知性を持った製品づくりを目指しています。

Fujitsubo's spirit is to "produce the highest quality products". This has not changed since Fujitsubo was first established in 1931. This spirit does not only pertain to creating highly efficient and high quality exhausts and manifolds, but it also applies to our customer's satisfaction. This is the reason Research and development is performed with people, motor vehicles, society, environment etc, all thought as one, to create a product through diversity.

また、FUJITSUBOは常に高度な技術を追求しています。ボッシュ社製4ホイール・シャシー・ダイナモや1/3オクターブバンド微分析計など、最新機器導入による重要データの蓄積。レーザー3次元加工機や自動制御パイプベンダーなどによる生産性の向上。CCDカメラ&画像解析ソフト、3D CADによる品質管理。実車実験によるトータル・パフォーマンスの追求。このような、研究、開発、生産体制が、EXマニホールドの集合部にみられる特殊技術を生み出しました。

Fujitsubo is continuously pursuing advanced technologies. A chassis dynometer, 1/3 octave band sound analysis device, and other specialized equipment are utilized to accumulate important data from the latest technologies. Increased productivity through advanced 3D laser processing machines and automated pipe benders. Strict quality control with CCD cameras, image analysis software, and 3D CAD. Cumulative performance analysis through actual vehicle testing. This type of research, development, and production structure has led to the Fujitsubo patented exhaust manifold (Pat. No. 1320379).

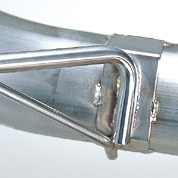

Joint

段差により排気流の乱れや漏れ、振動によるガタや緩みに対し、高精度加工によって、スムーズな排気と強度・軽量化を実現。また、特殊溶接技術により高いクオリティを確保。

High-precision processing achieves smooth exhaust, strength and light weight against turbulence and leakage of exhaust flow due to steps, and play and looseness due to vibration. High quality is ensured by special welding technology.

ストレート・レイアウト

Straight Layout

メイン・パイプからテール.パイプまで排気効率を追求。曲げが必要な部分での、その曲折率を最小限に抑え、さらに曲げにより生じるパイプ内面の歪みをFUJITSUBO独自の技術で解消。

Through research is performed on each application to find the most efficient and free flowing path for the exhaust from the main pipe to the exhaust tip.

軽量プレス成形フランジ

Lightweight Press Mold Flange

軽量化を追求し製品分割部に採用した軽量プレス成形フランジ。軽量化しながらも強度を確保している。

A lightweight press mould flange has been implemented in the product dissection department to research lightweight technology. Intense strength of t=2.3mm has been achieved (some products not included).

ロストワックス製法

Lost wax manufacturing method

緻密な製品クオリティと効果的な肉抜きで軽量化

Light weight with precise product quality and effective thinning.

フレキシブルジョイント

Donut type Joint

エンジンの振れ、振動や走行時の振動からのストレスを、フレキシブルジョイントにより効果的に逃がし、耐久性を飛躍的に高めている。

Stress on the exhaust system has been successfully decreased through high quality flex joints. Vibration from engine and chassis are absorbed by the flex joint reducing stress to the exhaust system.

専用軽量ブラケット

Dedicated lightweight bracket

スーパーTi、レガリススーパーR、パワーゲッター、RM-01A等で採用されている軽量ブラケットは強度、耐久性も十分に確保している。

The lightweight brackets used in Super Ti, Legalis Super R, Power Getter, RM-01A, etc. ensure sufficient strength and durability.

軽量中空パイプステ-

Lightweight hollow pipe stay

ヘッダー付軽量中空パイプステー。無垢材に比べ50%以上の軽量化とサポートゴムの抜け防止を実現。

Lightweight hollow pipe stay with header. We realize weight saving more than 50% in comparison with solid wood and prevention of support rubber coming off.

薄肉材へのステ-取付部

Stay mounting part for thin material

ベースプレートを介し応力の集中を防いでいる。

The concentration of stress is prevented through the base plate.

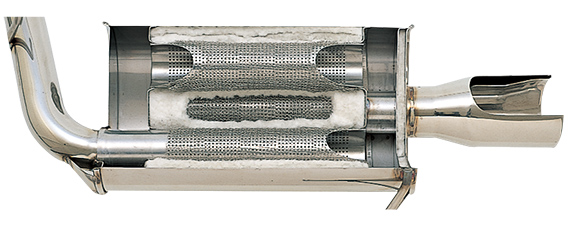

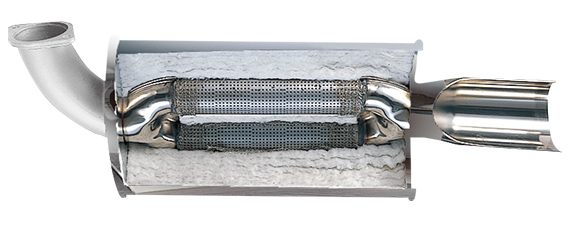

Main Silencer

高効率と消音効果を最大限に発揮させるため、各車種別にセッティングしている。消音材としてはパンチングパイプ、ステンレスデミスター、グラスウール、カットウール等を採用。排気効率の向上と、独自のサウンドチューニングによるスポーティーエグゾーストサウンドを実現している。

In order to maximize the high efficiency and noise reduction effect, it is set for each model.Punching pipes, stainless steel demisters, glass wool, cut wool, etc. are used as sound deadening materials. It achieves a sporty exhaust sound with improved exhaust efficiency and unique sound tuning.

ストレート構造

Straight structure

リアクティブ構造

Reactive structure

DPS構造(デュアルパイプシステム)

Dual pipe system structure

Face Process / Weld

表面加工

Surface processing

表面を研磨、ヘアラインなど製品や使用する場所毎に変更。美しい表面処理はハイクオリティの証です。

Change the surface for each product or place of use such as polishing and hairline. Beautiful surface treatment is proof of high quality.

SUS304ステンレス溶接部

SUS304 stainless weld

TIG溶接により、見た目の美しさを確保しつつ、さらに強度・耐久性をも兼ね備えています。

By TIG welding, it has good strength and durability while maintaining its beautiful appearance.

製品について

- 製品の構造は同種商品でも車種によって異なる場合があります。

- サイレンサー形状は製品及び車種により異なる場合があります。

- 排気管のダブル出口、左右出口の場合、均等に排気しないことがあります。

- 排気管が左右出口の場合、車両の個体差、諸条件等により左右均等に装着できない場合があります。

- 記載対応車種でも車両の個体差、諸条件等により装着できない場合があります。

- 不正改造車に取り付けた場合のクレームには応じかねますので、ご了承ください。

- スポーツマフラーは消耗部品です。経年変化等により、本来の性能が損なわれた場合には速やかに交換してください。

- エンジンコンディションが悪化した車両に装着した場合、カーボン等の発生により稀に排気音量が増大することがあります。

- 一部製品について装着車両の標準地上高が変わりますので、路面の突起物や駐車場の車輪止めなどに接触しないよう充分に注意してください。

- 製品は装着状態において走行後、熱による金属の収縮によりピーン・カーンといった音を発生する場合があります。

- 製品は材質の特性上、熱の影響等で変色します。

- 「スポーツキャタライザー」は第三者機関での自動車排出ガス試験成績表のコピーを添付しております。車検の際はお近くの車検場または検査機関へご相談ください。

- カシメ加工タイプのサイレンサーの場合、スポーツマフラーに要求される気密精度(0.03MPa時 吐出量10L/min)は保持していますが、一部車種によっては水滴が垂れる場合があります。

- FUJITSUBO製品は皆様に安心して御使用いただけるよう、ユーザー様の管理・登録を行っております。つきましては商品に同梱されているユーザー登録カード(登録ハガキ)を参照し、登録を行って下さい。

Racing Know-how

FUJITSUBOは常にチャレンジしています。スーパー耐久レースにおいて、FUJITSUBOインプレッサをサポート。サーキットのみならず、ジムカーナ、ダートトライアル等のカテゴリーでのサポートも行っており、こうした様々なジャンルのモーター・スポーツの現場から得られる人的、技術的ノウハウやデータも、時代に対応した新製品開発のための財産となって積み重ねられています。

Fujitsubo continues to challenge. The Fujitsubo Impreza takes part in the Super Taikyu endurance racing series. Valuable experience is acquired in a variety of motorsports activities. This assists in new product development and drives development of new innovative technologies, meeting the needs change, which is thought as a valuable asset.

国際規格「ISO9001:2015」認証取得

International standards ISO9001: 2015 Certification

ISO(International Organization for Standardization)とは、国際基準化機構のこと。ISO9001シリーズはその国際標準化機構の、品質保証に関する国際規格。FUJITSUBOではこのなかで、受注から設計、開発、製造、出荷に至るまでの厳しい要求項目を満たし、かつ維持しなければならない「ISO9001:2015」の認証を取得しています。

ISO (International Organization for Standardization) is the International Organization for Standardization. The ISO9001 series is an international standard for quality assurance of the International Organization for Standardization. Among them, FUJITSUBO has obtained ISO9001: 2015 certification, which must meet and maintain strict requirements from ordering to design, development, manufacturing, and shipment.